Auxiliary engines are essential components in maritime and industrial operations, providing power for various auxiliary systems and supporting the main engines. Their reliability is crucial for uninterrupted functionality, as any downtime can lead to operational delays and financial losses. Maintaining the efficiency of these engines requires not only routine servicing but also access to high-quality spare parts designed to meet their specific needs.

The role of genuine spare parts

Auxiliary engine spare parts play a pivotal role in maintaining the performance and longevity of these critical systems. These components are engineered to meet the exact specifications of the engines they support, ensuring seamless compatibility and optimal functionality. For auxiliary engines, which often operate under demanding conditions, the use of high-quality spare parts is indispensable in preventing wear and tear from escalating into major failures.

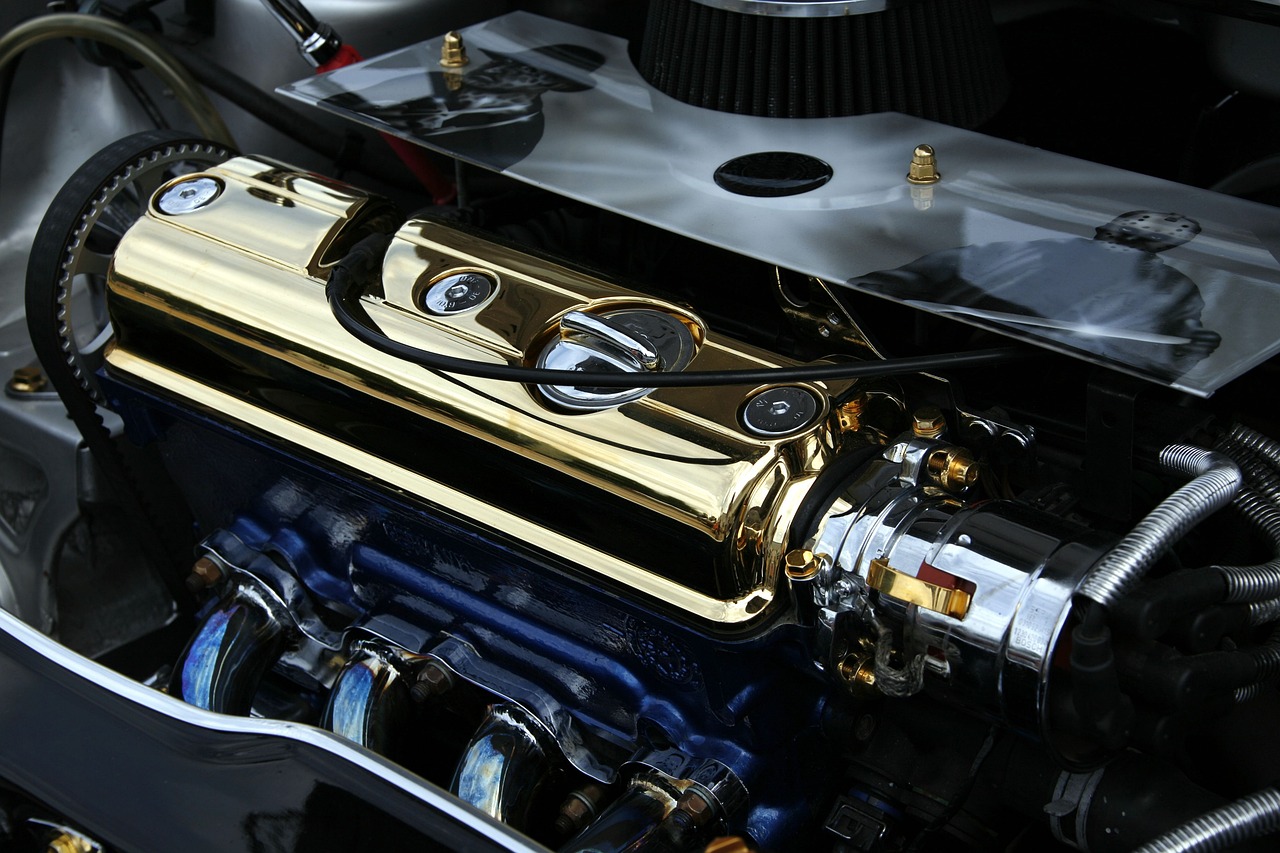

When it comes to sourcing „auxiliary engine spare parts,” it is essential to prioritize authenticity and precision. Original components such as pistons, cylinder liners, fuel injectors, and turbochargers are designed to withstand the intense pressure and high temperatures inherent to engine operation. Investing in genuine parts minimizes the risks associated with premature breakdowns and ensures consistent performance, which is vital for industries like shipping, where reliability is non-negotiable. Furthermore, non-authentic or substandard parts can lead to inefficiencies, reduced lifespan of the engine, and even safety risks.

Key components and their maintenance

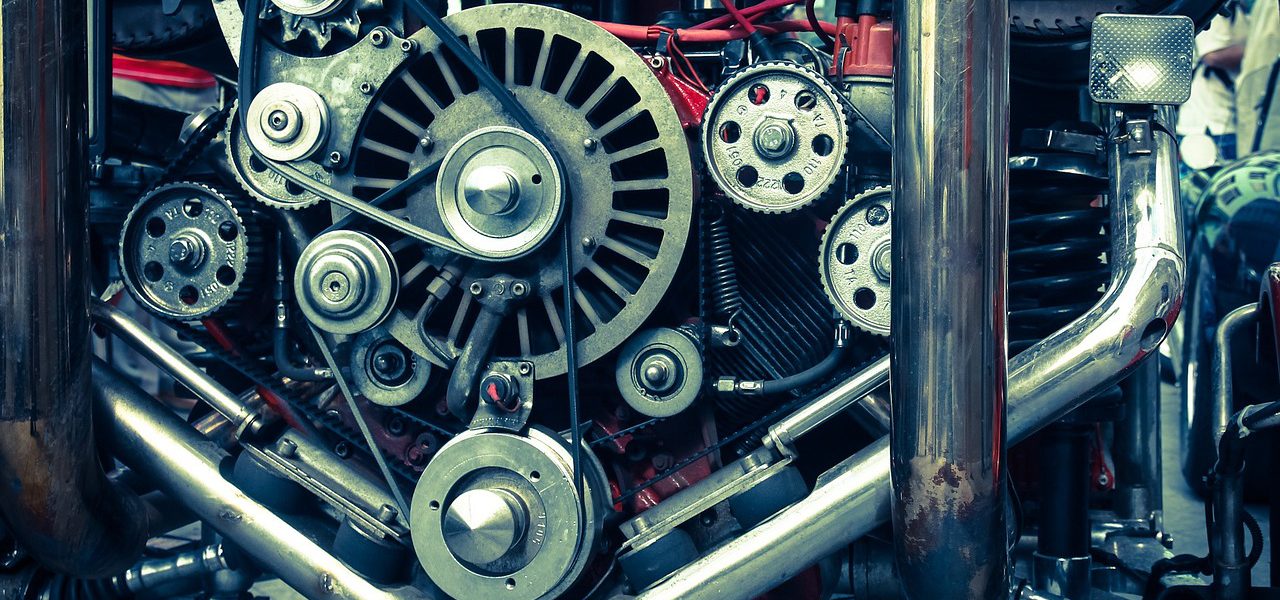

Auxiliary engines are complex machines composed of numerous interdependent parts, each of which requires meticulous care and maintenance. Among the most critical components are cylinder heads and liners, which must endure the constant exposure to high-pressure gases and extreme temperatures. Regular inspection and timely replacement of these parts are essential to avoid damage that could compromise the engine’s efficiency.

The fuel system, including injectors and pumps, is another area requiring close attention. This system ensures that the engine receives the precise amount of fuel for optimal combustion. Worn-out fuel injectors or faulty pumps can lead to incomplete combustion, resulting in increased fuel consumption and higher emissions. Replacing these components with reliable auxiliary engine spare parts helps maintain not only performance but also compliance with environmental regulations.

Additionally, the cooling and lubrication systems are indispensable in preventing overheating and ensuring smooth operation. Components such as oil pumps, water pumps, and seals should be regularly checked and replaced as needed to avoid costly repairs or extended downtime. Neglecting these vital systems can result in severe engine damage, underscoring the importance of using durable, high-quality spare parts.

Sourcing and managing spare parts

Efficient sourcing and management of auxiliary engine spare parts are critical to ensuring uninterrupted operation and minimizing downtime. Collaborating with trusted suppliers who specialize in marine and industrial engine parts is an effective way to guarantee access to high-quality components. Such suppliers often provide a comprehensive range of products, from routine maintenance items to specialized components, catering to diverse engine models and configurations.

Additionally, strategic inventory management can significantly enhance operational efficiency. Maintaining a stock of essential spare parts reduces the risk of delays caused by supply chain disruptions. Many suppliers now offer tailored maintenance kits, which include all the necessary components for scheduled overhauls, streamlining the procurement process. Furthermore, suppliers providing technical support and guidance can help operators make informed decisions about part compatibility and replacement intervals, ensuring that maintenance is performed proactively rather than reactively.

Conclusion

Auxiliary engines are indispensable in supporting the smooth operation of industrial and maritime systems, and their reliability hinges on proper maintenance and the use of high-quality spare parts. From cylinder liners and fuel injectors to lubrication systems and turbochargers, every component plays a critical role in ensuring optimal performance. Choosing genuine auxiliary engine spare parts not only extends the engine’s lifespan but also minimizes operational disruptions and maximizes efficiency. By partnering with reputable suppliers and adopting proactive maintenance strategies, operators can safeguard their investments and maintain seamless operations in even the most demanding environments.

Visit http://posejdon-marine.pl/ and find all the necessary spare parts to ensure your engine’s reliability and performance.